AF Series

Product Characteristics

Details of Product

Standard Specification

Product Characteristics

Characteristics of AF Series Products

Oil-free system of Kyungwon produces 100% oil-free air

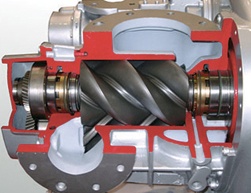

Oil-free airend acknowledged by the world

- Prevention of oil corrosion through the application of stainless 2- -step rotor with up to 60,000 hours of lifetime

- Efficiency of compressor increased by ultra coating rotor and housing, allowing for stable operation at high temperature and pressure

- Noise and durability improved by application of high-speed rotation and high-precision bull gear and timing gear

- Excellent cooling efficiency with the installation of internal oil jacket

- Function to produce customized products for different customer demands using diverse product groups and gear ratios

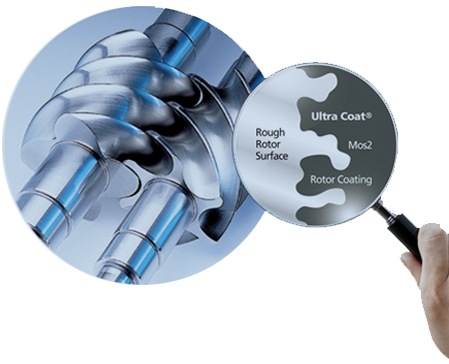

Special Ultra Coating

- Coating material:Molybdenum disulfide (MoS2) + high temperature organic resin + Tellon(clean content) +etc···

- At first test run direct contact space between rotors is being adjusted by itself

- High performance at 300 degrees C

- The tellon cover is a plastic material which is viable to leakage

After 4000 hours run energy saving is 10% more than the industry average

Airend with highest perfomance

- Airend of GHH, Germany boasting the world’s highest performance applied

- High efficiency and performance compared to competitors using a 2-step compression method

Best parts and optimal system

- Excellent cooling performance exhibited by 1-step I 2-step application of semi-permanent stainless pre- -cooler

- Occurrence of foreign substances suppressed by use of stainless mater al for both air & oil pipes

- Perfect removal of condensate using 3-step condensate removal system

- Increased reliability from application of hydraulic control inhalation valve

- Occurrence of oil vapor minimized through application of breather filter based on AOS method

Convenient maintenance

- Easy repair and maintenance using module design

- Multifunctional Micom controller allows for perfect control and convenient use

Energy conservation

- High efficiency motor, VSD specification, internal oil pump

Best safety

- Perfect machine protection through application of more than 20 safety devices

Low vibration and noise

- Vibration isolation structure applied to the cooling part and split module type noise structure selected

Details of Product

Details of AF Series Product

Stainless pipe

- Prevention of foreign substances and corrosion through the use of stainless pipe appropriate for compressed air with high temperature and humidity

- Lifetime expanded and oil leak minimized by using stainless pipe for oil line and application of metal sealing

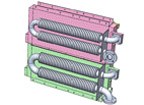

Application of Stainless Pre-Cooler

Use of Stainless Pre-Cooler for both primary and secondary discharge parts to increase cooling efficiency and reinforce durability

Hydraulic valve

- Stable operation with hydraulic control inhalation valve showing high reliability

- Accurate control under no-load at low pressure

3-step condensate removal system

- 3-step condensate removal system removes most of moisture before providing compressed air

- Semi-permanent use with installationol2-step inhalation and 2-step discharge cyclone moisture separator

- Flow type drain valve is installed in addition to 2-step airend for perfect prevention of moisture inflow

Oil pump

- Integrated oil pump structure maximizes energy efficiency through high durability and efficient power transmission

- Oilaccumulator installed to alleviate pulsation for protection of machine and prevention of oilleak

Easy maintenance selected

Module design offers convenient disassembly for inspection and maintenance, and convenience for maintenance was secured by metal sealing and swivel joint

AOS Breather Filter

- Breather filter applied with air-oil separator element manufacturing technology perfectly filters oil vapour in the oil tank

- Externalinstallation of breather pipe can be done depending on the conditions of use

Large capacity inhalation filter and oil filter

- Inhalation filter with decontamination efficiency of 99.9% is used in a large capacity for lifetime twice as long

- Large capacity oil filter combining differential pressure switch and bypass shows stable oil supply

Low noise and low vibration design

- Vibration minimized as all operating parts are made with vibration resistance design

- Fan noise minimized by installation olsplit module type silencer

- Inhaled air volume canbe adjusted by easy detachment and attachment olsplit module

Convenient Multi Micom Controller

- Convenient operation through key-pad arrangement considering driver’s motion

- Multilingual support (Korean, Chinese, English, Russian, Portuguese)

- Easy control by beginners through application of pyramid control method

- History monitoring of up to 160 items and stable operation, safely protecting your machine

Standard Specification

Standard specification of AF Series

| Compressor Type | Max.Working Pressure | Capacity | Motor Power | Noise | Dimension(LxWxH) | Weight | Air Outlet | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Bar | psig | ㎥/min | cfm | kw | HP | dB(A) | mm | kg | A(B) | |

| AF75 | 7.0 8.5 9.5 | 100 120 135 | 9.0 7.8 7.8 | 317 277 276 | 55 | 75 | 76 | 2300x1570x2090 | 2600 | 50(2) |

| AF100 | 7.0 8.5 9.5 | 100 120 135 | 12.2 10.6 10.6 | 431 375 374 | 75 | 100 | 78 | 2300x1570x2090 | 2800 | 50(2) |

| AF125 | 7.0 8.5 9.5 | 100 120 135 | 15.9 13.6 13.5 | 562 479 477 | 93 | 125 | 82 | 2700x1660x2350 | 3200 | 80(3) |

| AF150 | 7.0 8.5 9.5 | 100 120 135 | 19.5 16.0 16.0 | 688 566 565 | 110 | 150 | 83 | 2700x1660x2350 | 3250 | 80(3) |

| AF175 | 7.0 8.5 9.5 | 100 120 135 | 21.6 19.4 19.4 | 764 686 685 | 132 | 175 | 83 | 2700x1660x2350 | 3300 | 80(3) |

| AF200 | 7.0 8.5 9.5 | 100 120 135 | 26.0 25.9 22.9 | 917 915 810 | 160 | 215 | 83 | 2700x1660x2350 | 3350 | 80(3) |

| AF250 | 7.0※ 8.5※ 9.5※ | 100 120 135 | 32.8 29.4 29.3 | 1,158 1,038 1,036 | 190 | 250 | 84 | 3320x2150x2400 | 4250 | 100(4) |

| AF300 | 7.0 8.5 9.5 | 100 120 135 | 41.9 35.1 35.1 | 1,479 1,241 1,239 | 220 | 300 | 84 | 3320x2150x2400 | 4400 | 100(4) |

| AF350 | 7.0 8.5 9.5 | 100 120 135 | 45.7 41.8 41.8 | 1,613 1,478 1,476 | 260 | 350 | 85 | 3320x2150x2400 | 4650 | 100(4) |

| AF400 | 7.0 8.5 9.5 | 100 120 135 | 50.3 45.6 45.6 | 1,775 1,611 1,609 | 300 | 400 | 85 | 3320x2150x2400 | 4800 | 100(4) |

Specifications are subject to change without prior notice due to remodeling of products, etc.