AS V Series (Inverter Type)

Characteristics of AS V Series (Inverter Type)

Inverter (VSD) Air Compressor

is a necessity, not a choice!

Air demand analysis device (SCADAR SYSTEM) possessed by COAIRE offers a service for optimal compressed air system needed by your company

*We analyze your compressed air demand and perform energy diagnostics

Features & Benefits

- Technology verified by CE and UL certifications and high efficiency inverter with diverse ECM solutions

- Target pressure sett ng to reduce energy by up to 30%

- Free discharge pressure setting

| 1Inverter & control Box | 2Main Motor |

| Separator Tank | Airend |

| Suction Filter Assy | Fan Casing |

| Inverter Controller |

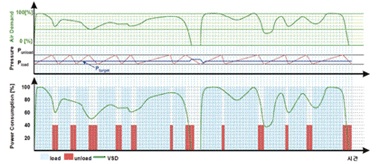

Examples of VSD operation

- Load rate: 76.7%

- Power load: 89.2%

- No-load power: 10.8%

- Power reduced by 10% under the same pressure compared to the standard when

- VSD is used

VSD stands for : Variable Speed Drive

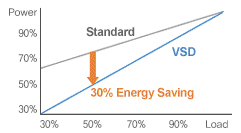

Energy conservation effective of VSD Screw Compressor

- Power saved by the no-load operation

– Free variation in speed quickly and precisely responds to fluctuation in air demand of the system - Compressed air required =prevents energy loss from the production of unnecessary compressed air

Energy conservation effective of VSD Screw Compressor

- System with large change in compressed air demand

– System in which air demand pattern greatly changes with operation of production line

– System with large deviation of air demand between night / day production lines

– System with large deviation of air demand according to fluctuation in production volume for each month season - Large capacity facility that simultaneously operates multiple compressors

– Standard screw (=base load) + VSD screw (top load) - System that requires constant pressure for consistent consumption of compressed air

Standard specification of AS V Series (Inverter Type)

| Compressor Type | Max.Working Pressure | Capacity | Motor Power | Noise | Dimension(LxWxH) | Weight | Air Outlet | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Bar | psig | ㎥/min | cfm | kw | HP | dB(A) | mm | kg | A(B) | |

| AS51V | 7.0 8.5 9.0 | 100 120 135 | 2.3~5.8 2.3~5.7 2.2~5.6 | 82~205 81~201 79~198 | 37 | 50 | 65 | 1660x1130x1607 | 1100 | 40(1 1/2) |

| AS76V | 7.0 8.5 9.0 | 100 120 135 | 4.2~10.4 3.6~8.9 3.4~8.5 | 147~367 126~314 120~300 | 55 | 75 | 72 | 2000x1210x1857 | 1730 | 50(2) |

| AS101V | 7.0 8.5 9.0 | 100 120 135 | 5.0~12.5 5.0~12.4 4.9~12.3 | 177~441 175~438 174~434 | 75 | 100 | 75 | 2000x1210x1857 | 1770 | 50(2) |

| AS151V | 7.0 8.5 9.0 | 100 120 135 | 8.3~20.7 8.1~20.3 8.0~20.1 | 292~731 287~717 284~710 | 132 | 175 | 78 | 3050x1470x2156 | 2970 | 65(2 1/2) |

| AS201V | 7.0 8.5 9.0 | 100 120 135 | 9.8~24.5 9.6~24.0 9.4~23.5 | 346~865 339~848 332~830 | 160 | 215 | 79 | 3200x1640x2156 | 3250 | 80(3) |

Specifications are subject to change without prior notice due to remodeling of products, etc.

Inverter (VSD) Air Compressor is a necessity, not a choice!

Air demand analysis device (SCADAR SYSTEM) possessed by COAIRE offers a service for optimal compressed air system needed by your company

*We analyze your compressed air demand and perform energy diagnostics

The sequence of energy reduction project [SCADAR SYSTEM]

Dispatch of compressed air system engineer

Analysis of the current system and compressed air usage pattern of the customer Data collected according to the configured cycle for at least 7 days and at most 14 days

Installation of air demand analysis device (SCADAR)

Determination of necessary conditions through the on-site survey on the customer’s air compression system and negotiation on details

Analysis on air compressor usage pattern

Information collected by air demand analyzer is used to submit analysis data on actual usage or usage pattern of each air compressor

Precise diagnostics and recommendation of optimal product composition

Consulting and data submission on the expected reduction in power cost and investment recollect on the period when the inverter air compressor is implemented

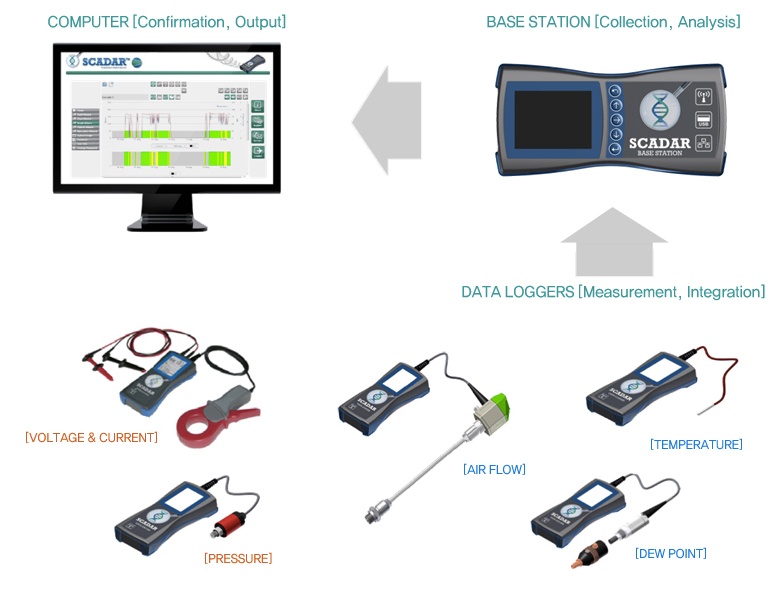

Air Demand Analysis Device

Air Demand Analysis Device [Air Demand Analysis Kit]

- Actual amount of air use or type of use has analyzed at the site

- Optimal product composition recommended as appropriate for conditions of use

- Data submitted by presenting power saving effect from minimized power consumption

SCADAR SYSTEM Measuring Equipment

OPTION: AIR VOLUME, TEMPERATURE, DEWPOINT

*Our company possesses all of the above measuring equipment for precise measurement.

Components of SCADAR SYSTEM

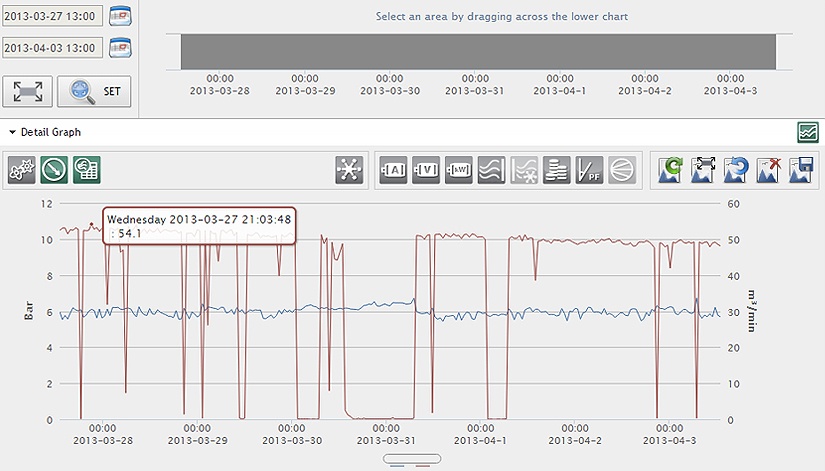

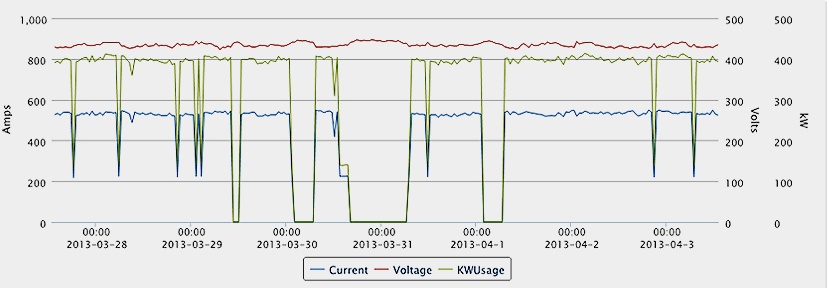

Measurement Data

We select your compressed air and pressure based on accurate measurement data for each time period, providing a service for optimal compressed air system.

Pressure & Flow Data

Current Power & Voltage Data

Energy Reduction Examples of Inverter Air Compressor

Manufacture of construction equipment parts [energy reduced by about 26%]

- Installed model: AS 120V(2 SETS)

- Installation date: January 2013

- Energy reduction expected after installation of a 100-horsepower inverter compressor and operating number management system in an existing manufacture line (expected reduction rate over 15%)

Painting and short industry [energy reduced by 15%]

- Installed model: AS 101v(1 SET)

- Installation date: March 2013

- Energy reduction expected after new installation of a 100-horsepower inverter compressor in an existing manulacture line and improvement on pipe leak (expected reduction rate over 20%)

Manufacture of machinery and gears[energy reduced by about 15%]

- Installed model:AS 101V(1 SET)

- Installation date: February 2014

- As a result of measuring energy consumption after installation of 100-horsepower inverter compressor and operating number management system ina new manufacture line, annual energy reduction of about 8,000,000 won was achieved

Manufacturer of automobile parts[energy reduced by 20%]

- Installed model: AS 101V(2 SETS)

- Installation date: April 2014

- As a result of measuring energy consumption after installation of 100-horsepower inverter compressor and operating number management system in a new factory, annual energy reduction